KOTITI Testing & Research Institute performs research and development study for all stages from fiber to garment to enhance domestic textile industry’s competitiveness.

Especially, KOTITI carries out various research themes such as new spinning technology, functionally new product, eco-friendly study, wearable electronics,

new test method and etc. Also, we are proceeding R&D study supported by government and joint research with private enterprises.

-

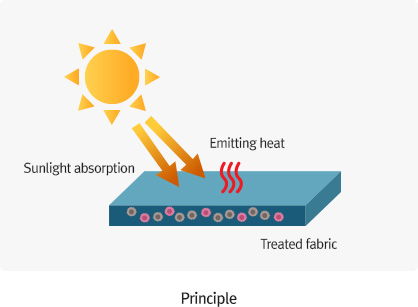

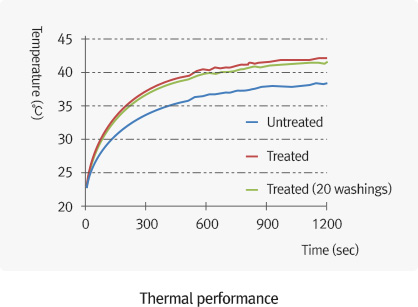

- X-heat

- Characteristics and advantages

-

- Emits heat immediately under the sunlight in outdoor environment (3 ~ 10 ℃)

- Has excellent durability against washing

- Maintains original characteristics, handle and soft touch

- Target materials

-

- Cotton, Polyester, Rayon, Nylon, Acrylic etc.

- Application

-

- Fiber, Woven fabric, Knitted fabric, Garment etc.

-

-

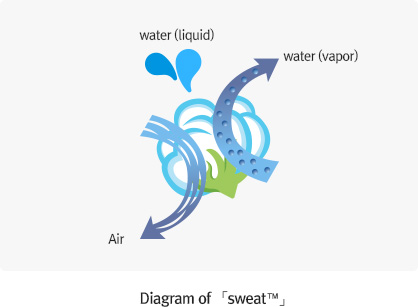

- X-sweat

- Introduction

-

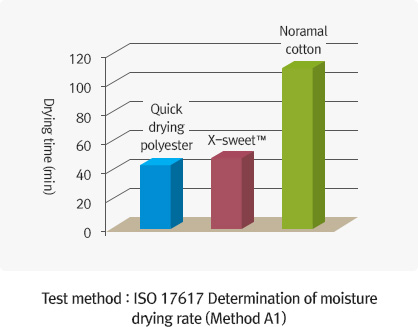

- 「X-sweat」 is cellulose textile product which has moisture absorption, quick drying, anti-cling and stain resistant properties. It also keeps its natural touch.

- Characteristics and advantages

-

- Excellent quick drying through fabrication with 「X-sweat」 and normal cotton.

- Comfort by anti-cling effect when wet with liquid such as sweat.

- Preventing hydrophilic liquid contaminants

- Superior laundry durability(20 times of laundry)

- Target material

-

- cotton and cotton/polyester blended products

- Application

-

- sport, casual and uniform material applicable

-

-

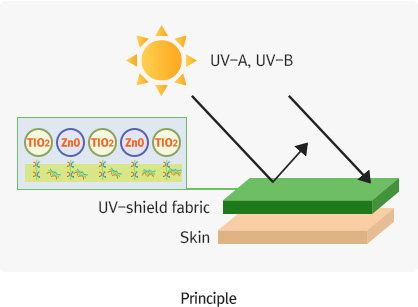

- UV-shield

- Introduction

-

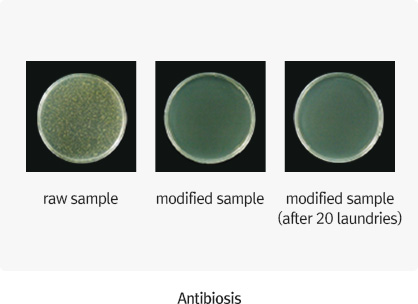

- 「UV-shield」 is a finishing technology using cosmetic ingredients which gives superior ultraviolet blocking and antimicrobial property to cotton products.

- Characteristics and advantages

-

- Cosmetic ingredients are used (titanium dioxide , zinc oxide and polysaccharides)

- Well-balanced UV-cut properties for UV-A, UV-B

- Superior UV-cut property (UPF 50+) and antimicrobial property last after 20 washings

- Target material

-

- cotton and cotton/polyester blended products and etc.

- Application

-

- sport, casual and uniform material applicable

-

-

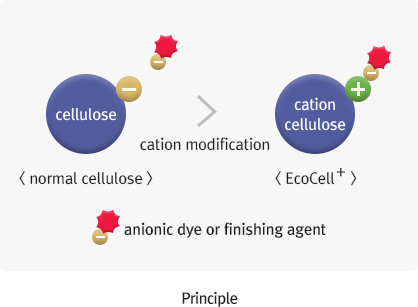

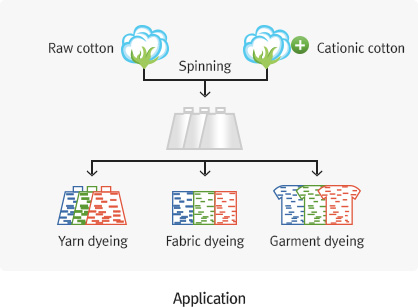

- EcoCell+

- Introduction

-

- 「 EcoCell+ 」 is cationic modification technology of cellulose fiber for manufacturing differential dyeing textile product.

- Characteristics and advantages

-

- Eco friendly dyeing process and CO₂ reduction effect

- Unique color pattern contributing superior aesthetic impression

- Shortening lead time corresponding for fast fashion

- Target material

-

- Cellulose materials including cotton, modal, viscose rayon, lyocell and blended products.

- Application

-

- Including melage yarn, patch yarn and nep yarn, multi-color fabric products material applicable

-

-

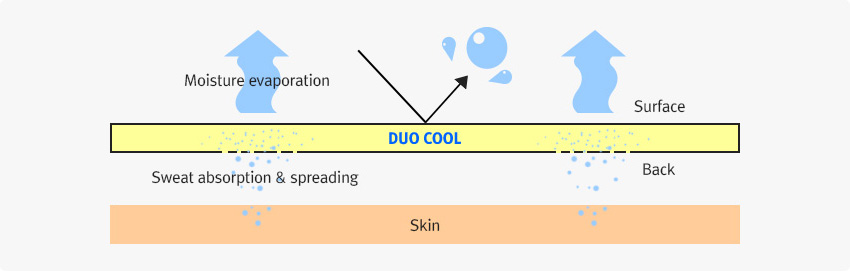

- One-side water repellent / one-side water absorbent finishing

- Introduction

-

- Comfortable environment between body and clothing due to quick absorption and transport sweat

- Good air circulation due to excellent air permeability

- Soft handle similar to normal product

- Target materials

-

- Cotton, Polyester, Rayon, Nylon, Acrylic and etc.

- Application

-

- Woven fabric, Knitted fabric etc.

-

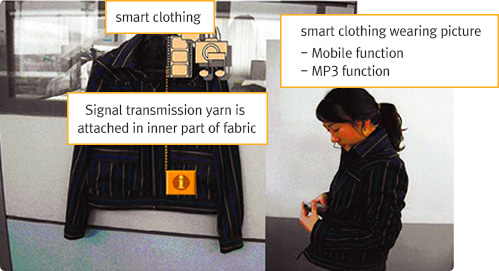

- Conductive Yarn

- Introduction

-

- 「 Conductive yarn 」 acts as signal carriers and helps to transmit electrical signals between digital device for wired or wireless communication.

- Characteristics and advantages

-

- The application of new manufacturing technology differentiated from the existing covering technology

- Maximize of both sheath coverage effect and the sheath/core cohesive force

- Minimize of slippage between core filament and sheath fibers

- Application

-

- ICT applications such as sport, casual, outdoor wear, backpack and etc

-

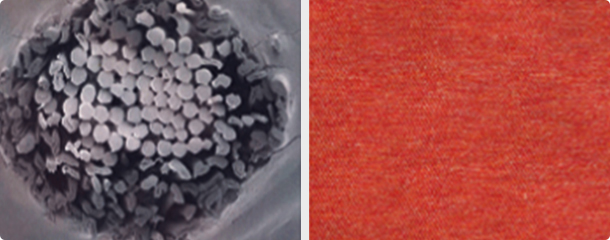

- Staple-Core Spun Yarn

- Introduction

-

- 「 Staple-Core Spun Yarn」 is a special structural yarn that different kinds of staple fibers(color or material) consist in core and sheath sector of single yarn separately.

- Characteristics and advantages

-

- The advanced staple-core spun yarn to apply various staple fibers such as natural fiber and synthetic fiber

- Appearance : Special look due to partial exposure of core fibers

- Touch : Soft & bulky, excellent crease recovery

- Function : Combination of natural and synthetic fibers

- Application

-

- Suit, sport, casual, interior and etc.

-

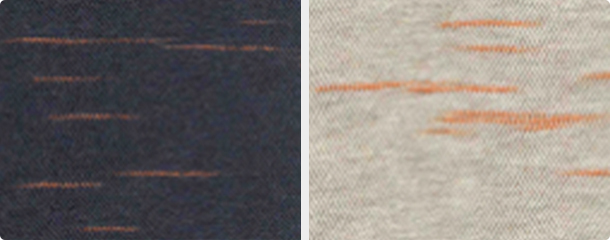

- Patched Yarn

- Introduction

-

- 「 Patched yarn 」 is a special structural yarn that the basic part of fibers are covered with different kinds of fibers periodically along the lengthwise direction of single yarn.

- Characteristics and advantages

-

- Unique slub appearance and touch created by patched fibers

- Manufacturing various products by controlling the color, period and length of patched fibers

- Application

-

- sport, casual, interior and etc.

-

- Multi-Structural Spun Yarn

- Introduction

-

- 「 Multi-structural spun yarn 」 consists of different kinds of fibers(staple or filament) appearing in inner and outer sector with a periodic alteration along the lengthwise direction of single yarn.

- Characteristics and advantages

-

- Unique mélange effect due to the periodic alteration of raw materials

- Double touch due to the mixing of raw materials

- Various functionality due to the mixture of natural and synthetic fibers

- Application

-

- sport, casual, suit, interior and etc.