- Test Analysis

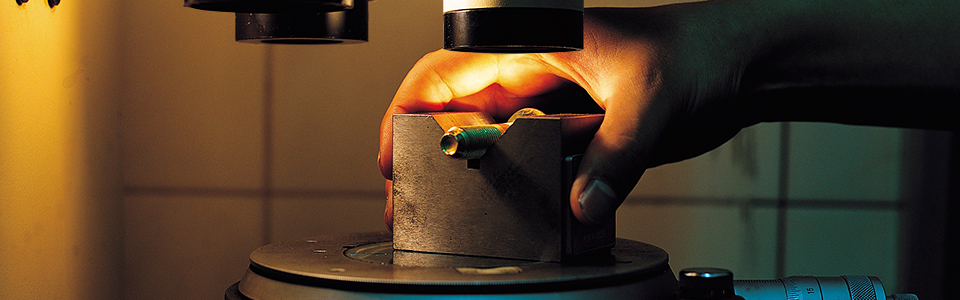

- Quality Inspection

- Business Support

- Product Safety Certification

- Research and Development

Copyright © KOTITI.

All right reserved.

All right reserved.

Total Inspection (100% Inspection) refers to the process of inspecting all products individually, sorting out defective products, and only passing non-defective products.

Total Inspection is Required..

- When inspecting expensive products.

- When inspecting critical defects.

- When the defect rate is high and screening is needed.

- When it is more economical than sampling inspection.

Total Inspection is Favorable…

- When even one mixture of defective product can cause a fatal flaw.

- When inspecting the characteristic that determines the main quality of high-value products.

- When inspecting the product with unreliable quality due to its unstable manufacturing process

- When inspecting low-quality products that most of the lots are rejected even with the Sampling Inspection.

- When it is easy and inexpensive to identify defective products.

- When inspecting small lot sized products.

Copyright © KOTITI. All right reserved.