SITE MAP

Business

- Testing & Analysis

-

Textile & FashionLiving & Consumer ProductsBio & HealthEnvironmental SafetyMaterials & Components

- Quality Inspection

- Product Safety & Certification

- Research & Development

- Business Support

Sustainability Management

Announcements

Customer Support

- Service Guide

About KOTITI

- PR Center

- Location

제품의 로트로부터 시료를 발췌하여 채취된 물품을 조사하고 해당 결과를 판정 기준과 비교하여 로트의 합격, 불합격을 결정하는 방법입니다.

샘플링 검사가 필요한 경우

- 파괴검사의 경우 (재료의 인장강도 시험, 전구나 진공관의 수명시험)

- 연속체나 대량 품

- 다수 다량의 것으로 어느 정도 불량품이 섞여도 괜찮을 경우

- 검사항목이 많은 경우

- 검사비용을 적게 하는 편이 이익이 되는 경우

- 생산자에게 품질향상의 자극을 주고 싶을 경우

샘플링 검사가 유리한 점

- 1개의 로트의 크기가 커서 전수 검사 비용의 부담이 있는 경우

- 일부 제품에 대해서 검사 결과가 합격인 경우 그 결과가 전체 로트를 대표할 수 있음

- 합격 로트 중에도 어느 정도까지는 불량품이 섞여 들어가는 것을 허용

-

-

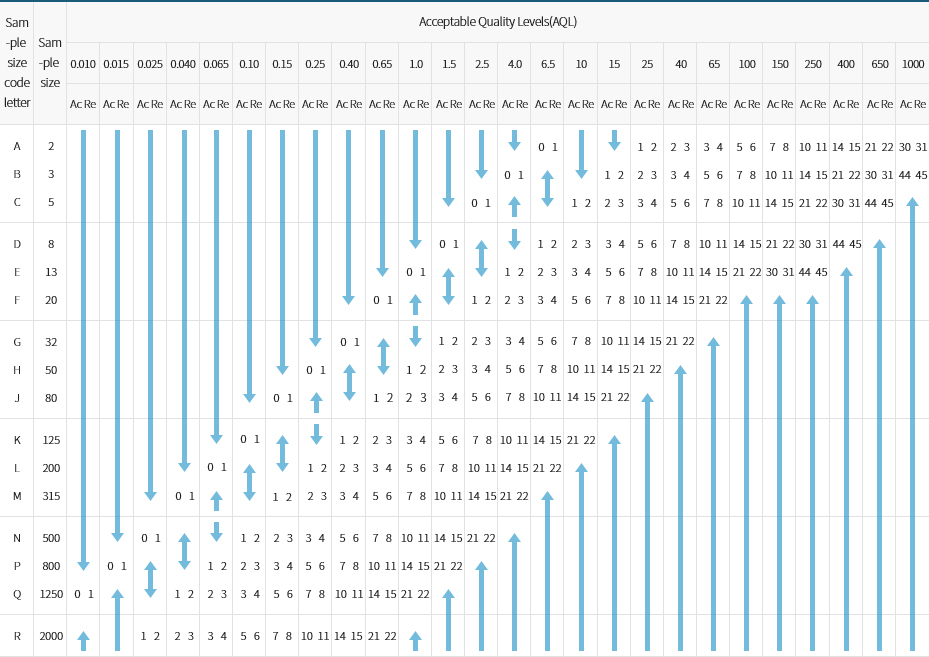

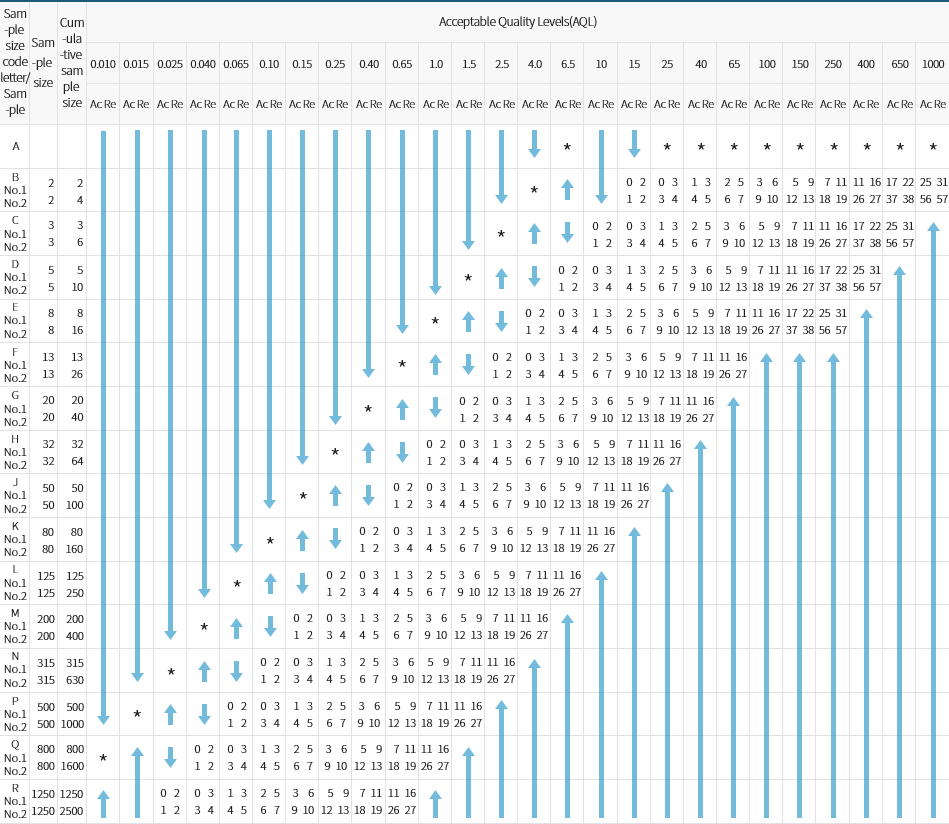

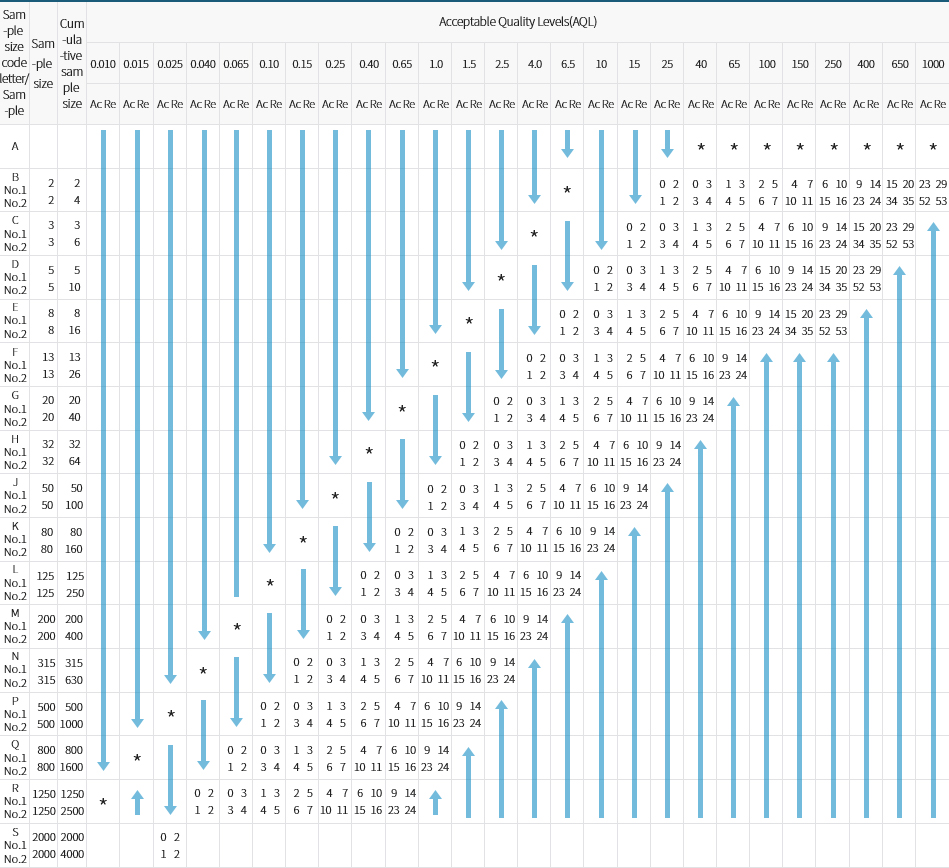

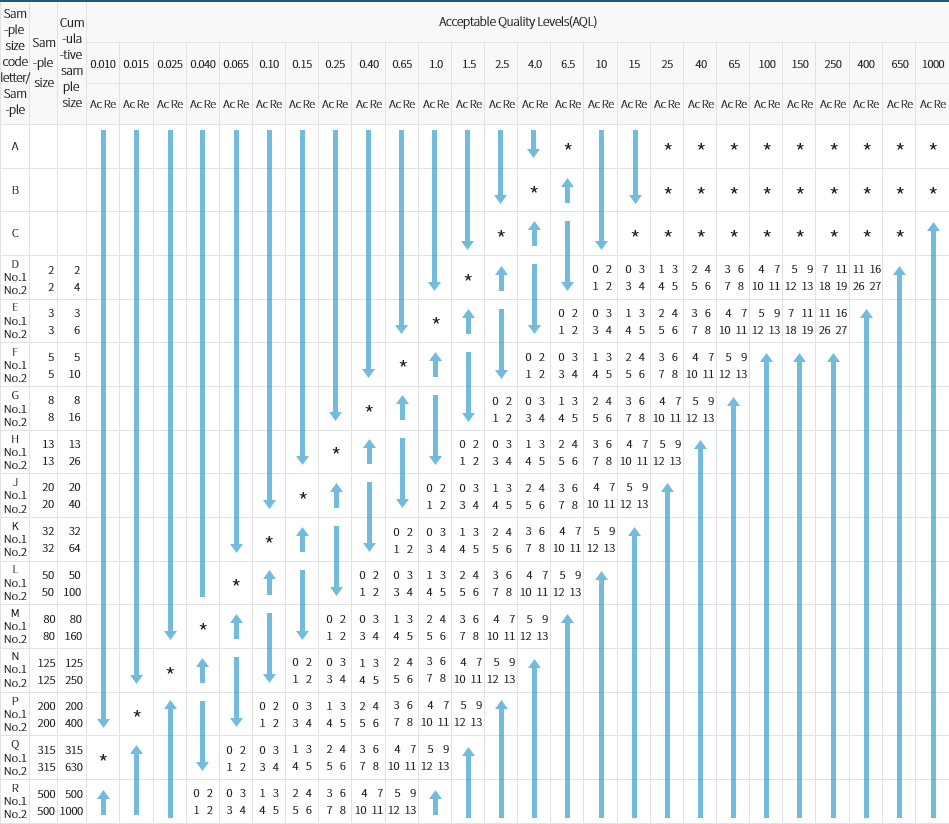

01보통 검사

프로세스 평균이 AQL과는 다르다고 의심하는 이유가 없는 경우에 사용

-

-

-

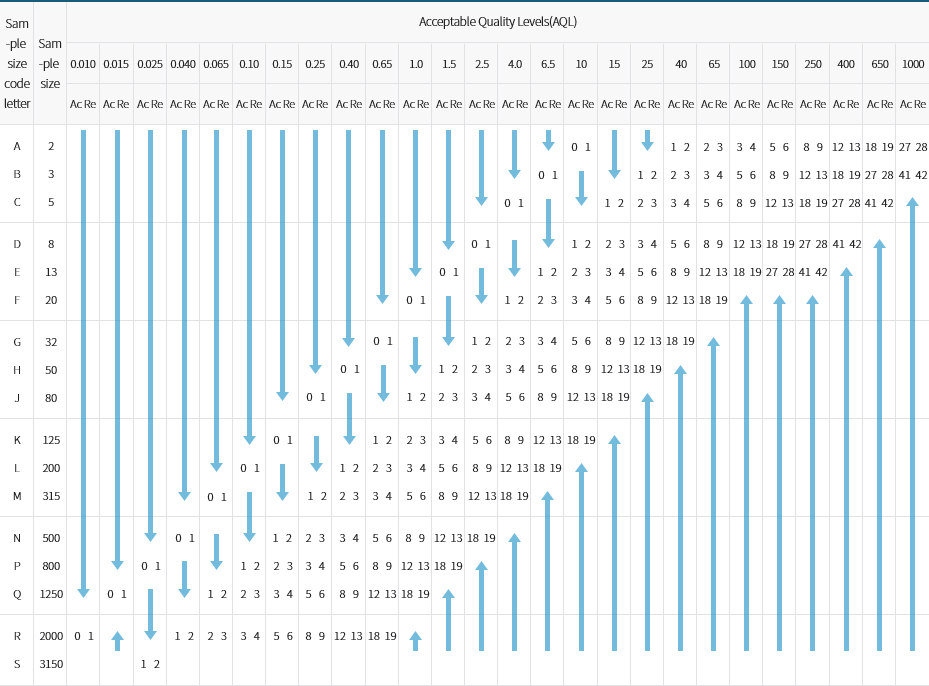

02까다로운 검사

미리 결정된 수의 연속 로트의 검사 결과에서 프로세스 평균이 AQL보다도 나쁘다는 것을 나타냈을 때 사용

-

-

-

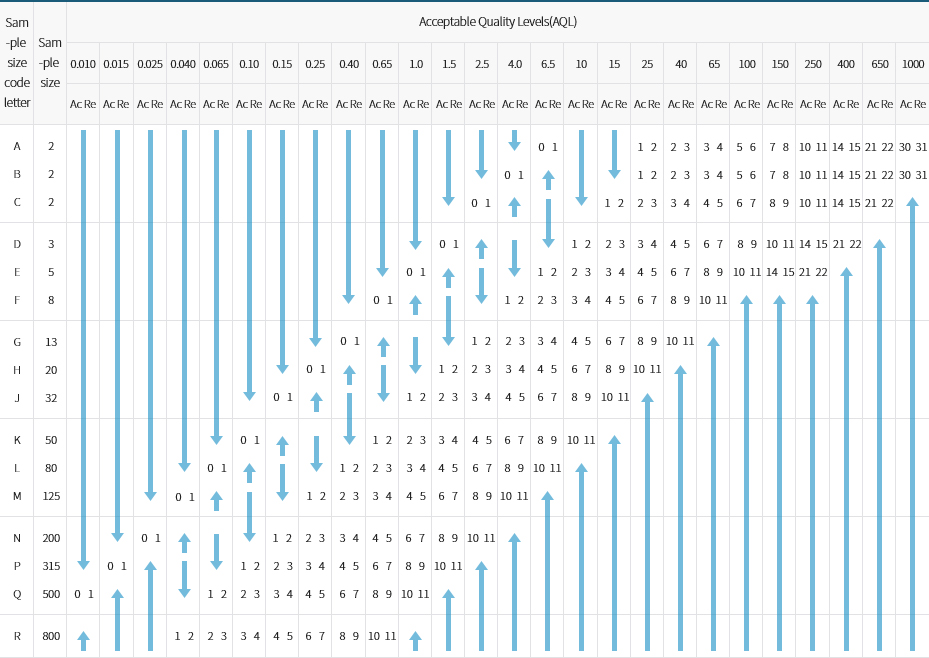

03수월한 검사

보통검사보다는 작은 샘플크기를 가진 샘플링 검사 방식 판단력은 보통검사 보다 떨어짐.

미리 결정된 수의 연속 로트의 검사 결과에서 프로세스 평균이 AQL보다도 좋다는 것을 나타냈을 때 사용

-

-

- Sample size Code Letters

-

Sample size Code Letters 로크 크기

(Lo Size)특별 검사 수준

(Special Instruction Levels)통상 검사 수준

(General inspection Levels)S - 1 S - 2 S - 3 S - 4 I II III 2 to 8 A A A A A A B 9 to 15 A A A A A B C 16 to 25 A A B B B C D 26 to 50 A B B C C D E 51 to 90 B B C C C E F 91 to 150 B B C D D F G 151 to 280 B C D E E G H 281 to 500 B C D E F H J 501 to 1200 C C E F G J K 1201 to 3200 C D E G H K L 3201 to 10000 C D F G J L M 10001 to 35000 C D F H K M N 35001 to 150000 D E G J L N P 150001 to 500000 D E G J M P Q 500001 and over D E H K N Q R