SITE MAP

Business

- Testing & Analysis

-

Textile & FashionLiving & Consumer ProductsBio & HealthEnvironmental SafetyMaterials & Components

- Quality Inspection

- Product Safety & Certification

- Research & Development

- Business Support

Sustainability Management

Announcements

Customer Support

- Service Guide

About KOTITI

- PR Center

- Location

Biodegradability

KOTITI provides precise testing and analysis services for biodegradability, disintegration, and ecotoxicity under various conditions, in compliance with domestic standards.

As the shift toward eco-friendly materials accelerates, scientific and reliable verification of biodegradability has become increasingly necessary. Based on accumulated analytical capabilities and testing infrastructure, KOTITI evaluates the safety and environmental impact of biodegradable materials comprehensively, supporting quality assurance and reliability.

What is Biodegradability (Compost·Soil Conditions) Testing?

- This test simulates the exposure of biodegradable plastics to different inoculated environments (e.g., compost, soil, marine) and determines biodegradability by continuously measuring the decomposition products or consumed substances generated through microbial activity over a given period and under specified environmental conditions.

| Simulated Environments | Industrial Composting Facilities | Home Compost | Natural Soil |

|---|---|---|---|

|

|

|

|

| Relevant Standards |

|

|

|

| Duration |

|

|

|

| Target |

|

||

| Required Sample Amount |

|

|

|

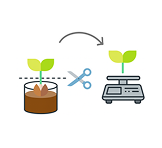

Biodegradability Test Flowchart (ISO 14855-1)

-

- pH ratio, C/N ratio, dry solid content (%), volatile solid content (%)

-

- Test Material

Frozen and Milled

Powder (250–500 μm)

- Test Material

-

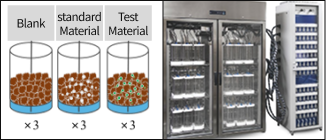

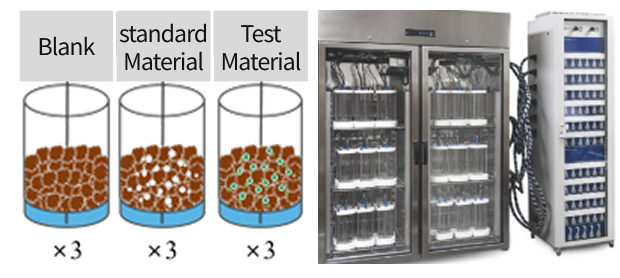

- Prepare a total of 9 test vessels, thoroughly mix and load the standard material and test material, then connect them to the biodegradability testing equipment.

- Continuously measure CO₂ generation for 45 to 180 days.

-

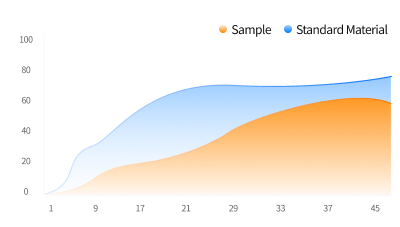

- Biodegradability (%)

- =

-

[(CO₂)T– (CO₂)B]ThCO2

- X 100

- (CO₂)T : Cumulative carbon dioxide generated from the vessel containing the test material (g/vessel)

- (CO₂)B : Average cumulative carbon dioxide from the blank control vessel (g/vessel)

- ThCO2: Theoretical amount of carbon dioxide generated by the test material (g/vessel)

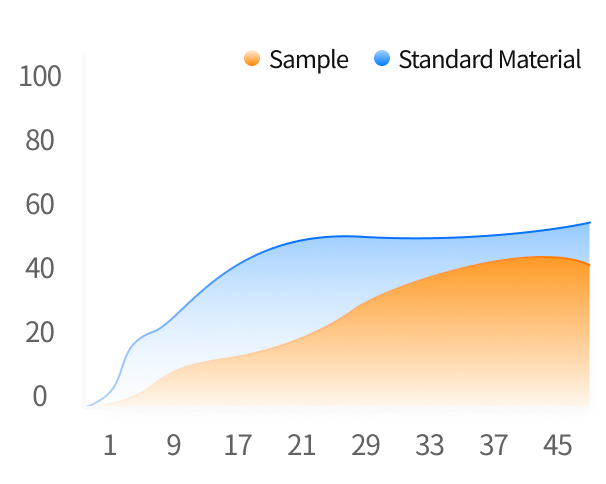

Derivation of Biodegradability Curves for the Standard Material and Test Material

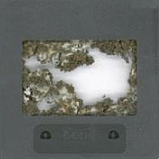

Residual Microplastics After Biodegradation(In-House Method)

-

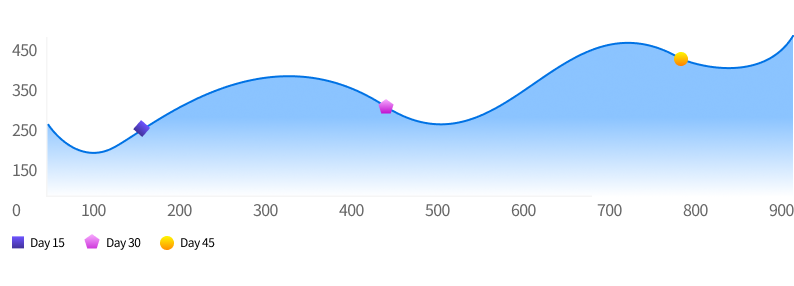

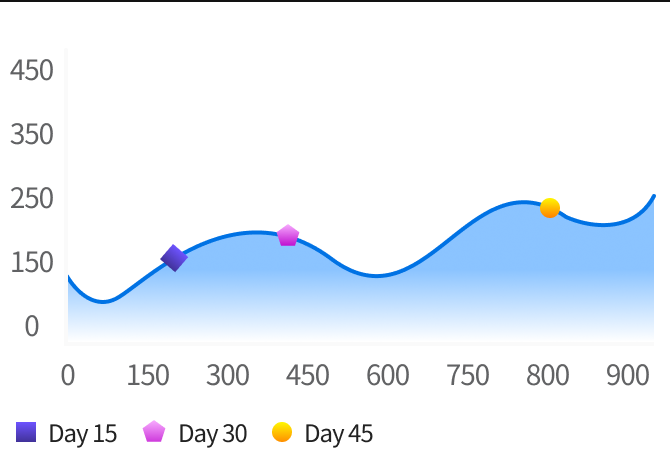

Biodegradable plastics are designed to break down more easily than conventional plastics, which means they can quickly fragment into fine particles during the biodegradation process. Therefore, an in-house testing method has been newly introduced to visually monitor the size and quantity of biodegradable micro-particles generated at different stages of the biodegradation period.

* Analysis is only applicable to biodegradable plastics.

-

Conduct biodegradation test

Conduct biodegradation test n days elapsed

-

Collect a specific amount

Collect a specific amount

of test material Pre-treatment

(organic matter oxidation and density separation, etc.)-

FT-IR

FT-IR

microplastic analysis- Microplastic Distribution Graph

- Allows observation of the size and distribution of microplastics at different stages of the biodegradation period

Application Procedure

-

01

Submit Application

-

02

Issuance of Quotation and Tax Invoice

-

03

Payment Confirmation

-

04

Testing and Analysis

-

05

Test Completion

-

06

Issuance of Test Report

Email Address Lookup

팝업 닫기Here is the requested email address.