SITE MAP

Business

- Testing & Analysis

-

Textile & FashionLiving & Consumer ProductsBio & HealthEnvironmental SafetyMaterials & Components

- Quality Inspection

- Product Safety & Certification

- Research & Development

- Business Support

Sustainability Management

Announcements

Customer Support

- Service Guide

About KOTITI

- PR Center

- Location

R&D Overview

The PILOT Process Research Center has established Korea’s first pilot-scale spinning and dyeing line, covering the entire process from spinning to dyeing.

The center supports domestic textile and fiber companies by developing advanced spinning technologies, conducting material evaluations,

and producing small-batch prototypes. In addition, it supports chemical materials and plastic processing companies

through processing technology development, material evaluation, and functional research utilizing its extrusion and injection molding facilities.

Major Developments list

-

- 01Multi-Effect yarn

- Characteristics & Advantages

- Special spinning technology that enables the production of four types of yarns

(slub, patched, gradation, and multi-cross yarn) on a single ring spinning frame - Superior aesthetics and enhanced sensory effects achieved through random- pattern feeding of multi-colored, multi-type fibers

- Capability to manufacture highly differentiated spun yarns through the combination of diverse fiber materials

- Target materials

- Cotton, polyester, and other fibers

- Various blended fiber materials

- Applications

- Sportswear

- Fashion apparel

- Interior textiles, etc.

-

- 02Multi-Effect Nep yarn

- Characteristics & Advantages

- Technology for producing nep yarn through a specialized carding process without additional processing steps

- High cost efficiency achieved by shortening the nep manufacturing process

- Enhanced and differentiated performance compared to conventional products in terms of appearance and hand feel, enabling the production of a wide range of nep types

- Target materials

- Cotton, polyester, and other fibers

- Various blended fiber materials

- Applications

- Sportswear

- Fashion apparel

- Interior textiles, etc.

-

- 03Multi-Structural Spun Yarn

- Introduction

- 「 Multi-structural spun yarn 」 consists of different kinds of fibers(staple or filament) appearing in inner and outer sector with a periodic alteration along the lengthwise direction of single yarn.

- Characteristics and advantages

- Unique mélange effect due to the periodic alteration of raw materials

- Double touch due to the mixing of raw materials

- Various functionality due to the mixture of natural and synthetic fibers

- Application

- sport, casual, suit, interior and etc.

-

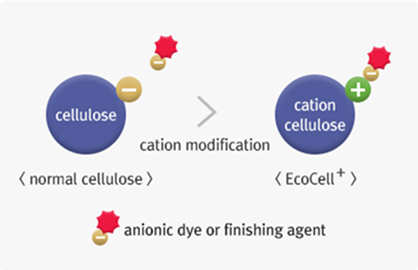

- 04EcoCell+

- Introduction

- 「 EcoCell+ 」 is cationic modification technology of cellulose fiber for manufacturing differential dyeing textile product.

- Characteristics and advantages

- Eco friendly dyeing process and CO₂ reduction effect

- Unique color pattern contributing superior aesthetic impression

- Shortening lead time corresponding for fast fashion

- Target material

- Cellulose materials including cotton, modal, viscose rayon, lyocell and blended products.

- Application

- Including melage yarn, patch yarn and nep yarn, multi-color fabric products material applicable

-

Principle

-

Application

-

- 05Care Cell

- Characteristics & Advantages

- High-durability antibacterial cellulose fiber finish technology

- Washable more than 100 times

- Use of cosmetic-grade ingredients

- Target materials

- Cellulose fibers (cotton, modal, Tencel and rayon, etc.) and their blended materials

- Applications

- Underwear, sportswear, outdoor, and casual apparel

- Maternity textiles (e.g., nursing bras)

- Home textiles, bedding, and masks

- Hygiene products (e.g., wound-care bandages)

-

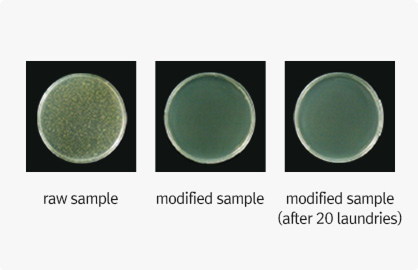

- 06UV-shield

- Introduction

- 「UV-shield」 is a finishing technology using cosmetic ingredients which gives superior ultraviolet blocking and antimicrobial property to cotton products.

- Characteristics and advantages

- Cosmetic ingredients are used (titanium dioxide , zinc oxide and polysaccharides)

- Well-balanced UV-cut properties for UV-A, UV-B

- Superior UV-cut property (UPF 50+) and antimicrobial property last after 20 washings

- Target material

- cotton and cotton/polyester blended products and etc.

- Application

- sport, casual and uniform material applicable

-

Principle

-

Antibiosis

-

- 07DRY·est

- Characteristics & Advantages

- Water-repellent polyester staple fiber finish technology

- Cost-effective functional yarn

- Enhanced moisture absorption and quick-drying performance and reduced clammy sensation.

- Use of PFCs-free compounds

- Target materials

- 100% polyester and polyester blended materials

- Applications

- Sportswear

- Casual wear

- Underwear

- Socks

-

- 08X-heat

- Characteristics and advantages

- Emits heat immediately under the sunlight in outdoor environment (3 ~ 10 ℃)

- Has excellent durability against washing

- Maintains original characteristics, handle and soft touch

- Target materials

- Cotton, Polyester, Rayon, Nylon, Acrylic etc.

- Application

- Fiber, Woven fabric, Knitted fabric, Garment etc.

-

Principle

-

Thermal performance

Email Address Lookup

팝업 닫기Here is the requested email address.